The advent of products such as insulated cooler bags has changed the way humans store food, beverages and other items that must be kept in place. Many people are ditching their old-fashioned coolers in favor of light, lightweight insulated cooler bags. Our factory offers insulated cooler bags with your logo in different sizes

Material of insulated cooler bag

1. Oxford cloth + tin foil

The exterior is made of oxford cloth, which is characterized by its sturdiness and good energy. The entry of air can be effectively avoided. Generally, the insulation time of Oxford cloth is 1 to 3 hours, which depends on the external environment and the thickness of the insulation layer. The inner surface of the food incubator is mostly tin foil. The tin foil can block the movement of air, collect heat, and then achieve thermal insulation. This kind of thing is very common in takeaway coolers

2. Environmentally friendly EPP

Environmentally friendly EPP is also called polypropylene plastic foam material. It has light specific gravity, good elasticity, shock resistance and compression resistance, high deformation recovery rate, good absorption performance, oil resistance, acid resistance, alkali resistance, resistance to various chemical solvents, non-absorbent, insulation, and heat resistance. (-40~130℃), non-toxic and tasteless, 100% recyclable and almost no degradation in performance, it is a real environment-friendly foam. This kind of food incubator is simple and easy to carry, durable and wear-resistant. The heat preservation time is relatively long, about 3 hours, and the price is a little more expensive. In addition, because of its non-toxic and high temperature resistance, it is also widely used in food packaging and microwave heating.

Features of insulated cooler bag

1. Good thermal insulation effect

2. It has good impact resistance, it is not easy to break under heavy pressure or impact, and will not leave scratches.

3. Food grade environmental protection material, non-toxic and tasteless, anti-ultraviolet, not easy to change color.

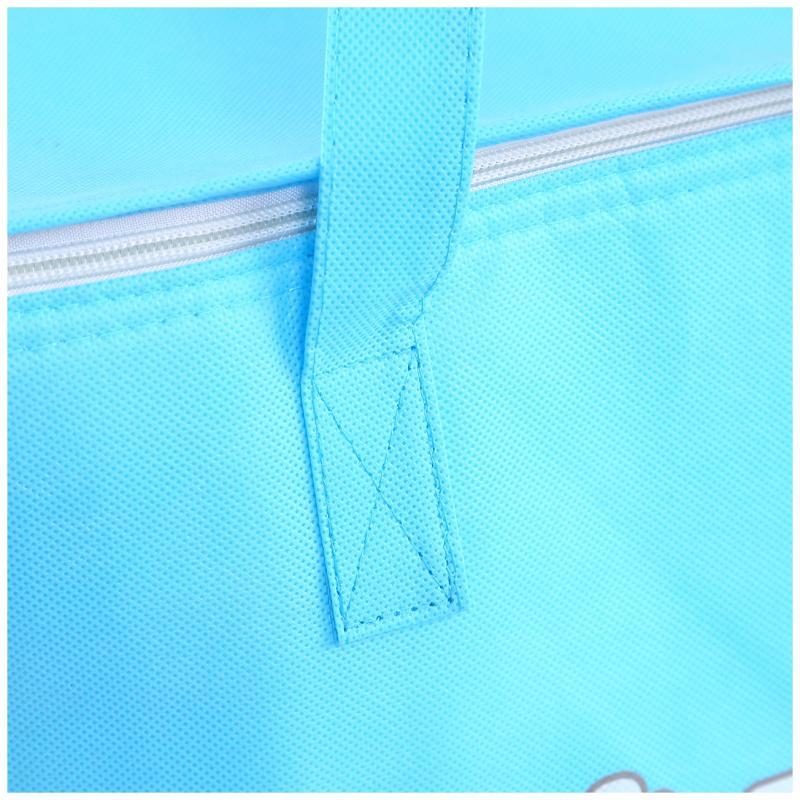

4. The sealing of the insulation bag is the first consideration. Although different brands of products have different sealing methods and packaging styles, excellent sealing is a necessary condition for the long-term preservation of stored food.

5. The high-quality thermal insulation bag has 200 times lower moisture permeability than similar products, and the preservation time is longer

Purpose of insulated cooler bag:

Insulation packs are widely used in daily life, and have good cold, heat and fresh-keeping functions. It is used in large quantities for the well-known takeaway delivery, and can also be used to carry work meals, summer iced fruits, winter milk tea and coffee insulation, seafood delivery and preservation, camping dinners, etc.

It will also be used for refrigerated transportation of medicines, vaccines and other products.

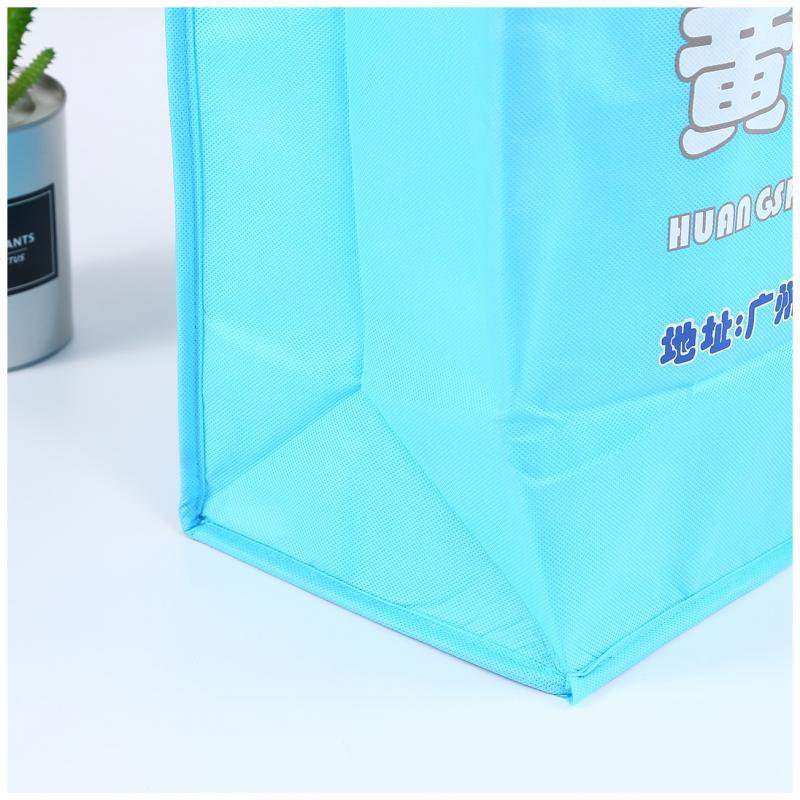

With the improvement of living standards and the pursuit of quality by consumers, many businesses and enterprises, in order to better promote their brands, choose to customize thermal insulation bags in batches, and print their own brand advertisements on the bags, so that their own Customers feel the company's special gifts, or the comfortable temperature of the merchant's products to achieve better brand promotion and enhance their brand influence

We offer customized insulated cooler bag with your logo

Insulated cooler bags are generally screen printing, color patterns, non-woven insulation bags can choose film or thermal transfer, offset printing. Oxford cloth or polyester insulation bags will mostly choose thermal transfer. |

The size of insulated cooler bag is different according to different usage scenarios, and the size requirements are also different. We provide customers with various customized sizes

We provide customers with insulated cooler bags in various colors

How to choose an insulated cooler bag

In the manufacture of insulated cooler bag, in order to make the bag have better thermal insulation effect, the choice of airtightness and material is particularly important. In the market, we can often see the use of aluminum foil as the surface or inner fabric of thermal insulation bags. The advantage of aluminum foil is that it can block radiant heat, allow heat to pass through conduction and convection, and maintain the temperature in the bag.

In addition, we can also see in the market that a material called PVC is used instead of aluminum foil. Using this material can make the thermal insulation bag look like a normal bag, and the shape also takes into account the daily use. It is used in the function of heat preservation, but the higher the temperature of the PVC material, the more likely it will become soft and the plasticizer will dissolve, so this material is more suitable for use in ice packs.

In order to avoid users' health concerns and take into account the shape of the thermal insulation bag, we choose another insulated cooler bag called food-grade PEVA, an environmentally friendly material. This material is characterized by soft and comfortable texture and no high-temperature dissolution of plasticizers. problem, you can use it with peace of mind